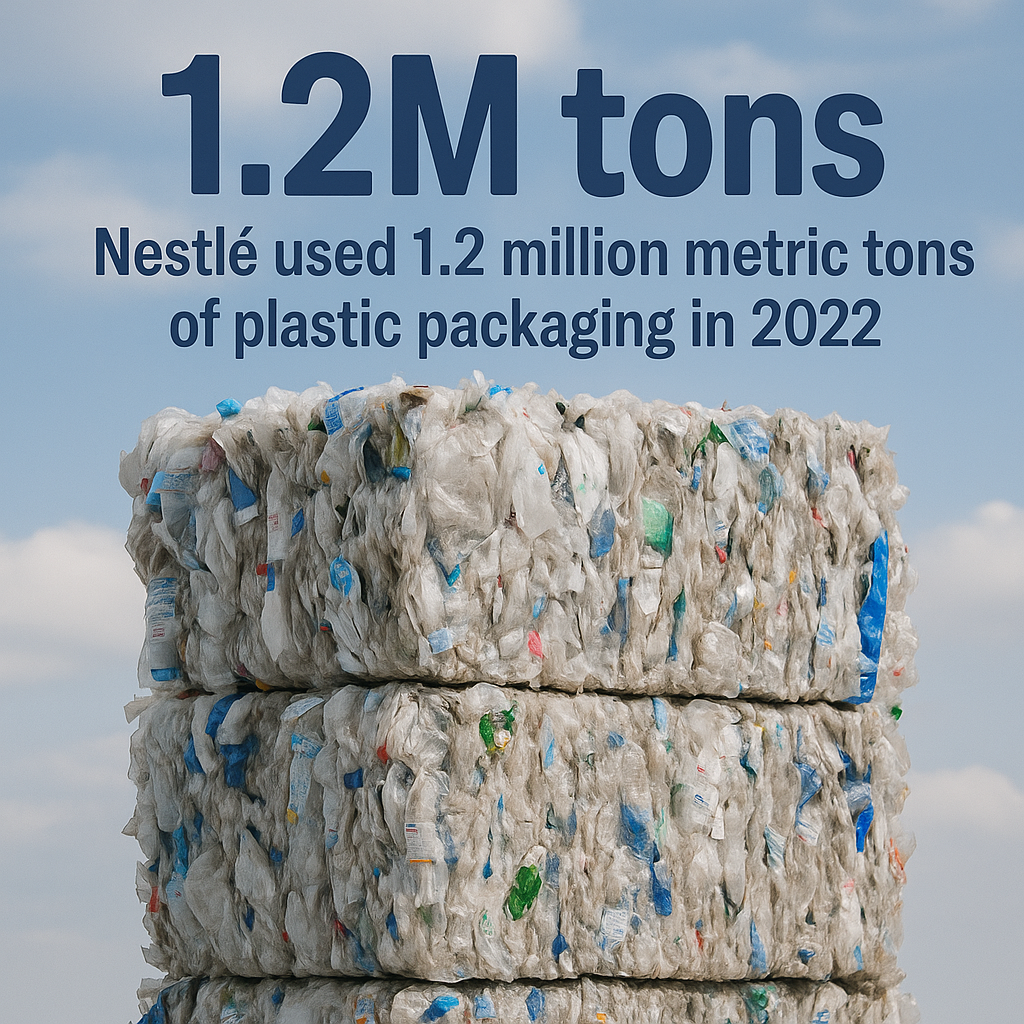

The Plastic Packaging Problem

Too much waste, too little recycling. Nestlé must lead the shift.

Nestlé Objective: To ensure that 100% of its packaging is recyclable or reusable by 2025, while reducing environmental impact and leading innovation in sustainable packaging.

Vision

To transform Nestlé’s packaging into a smart, circular system where waste becomes value, leveraging nature-based materials, digital traceability, and consumer engagement to drive a future where no packaging ends up as pollution.

Pack2Nest

Where Packaging Finds Its Way Home

1. BioBoost Materials

Sustainable packaging made from food waste and bioplastics to reduce emissions.

2. SmartPacks

QR-enabled packs that guide recycling, reward consumers, and generate real-time insights.

3. LoopBack

Return stations collect and compact used packs for recycling or reuse.

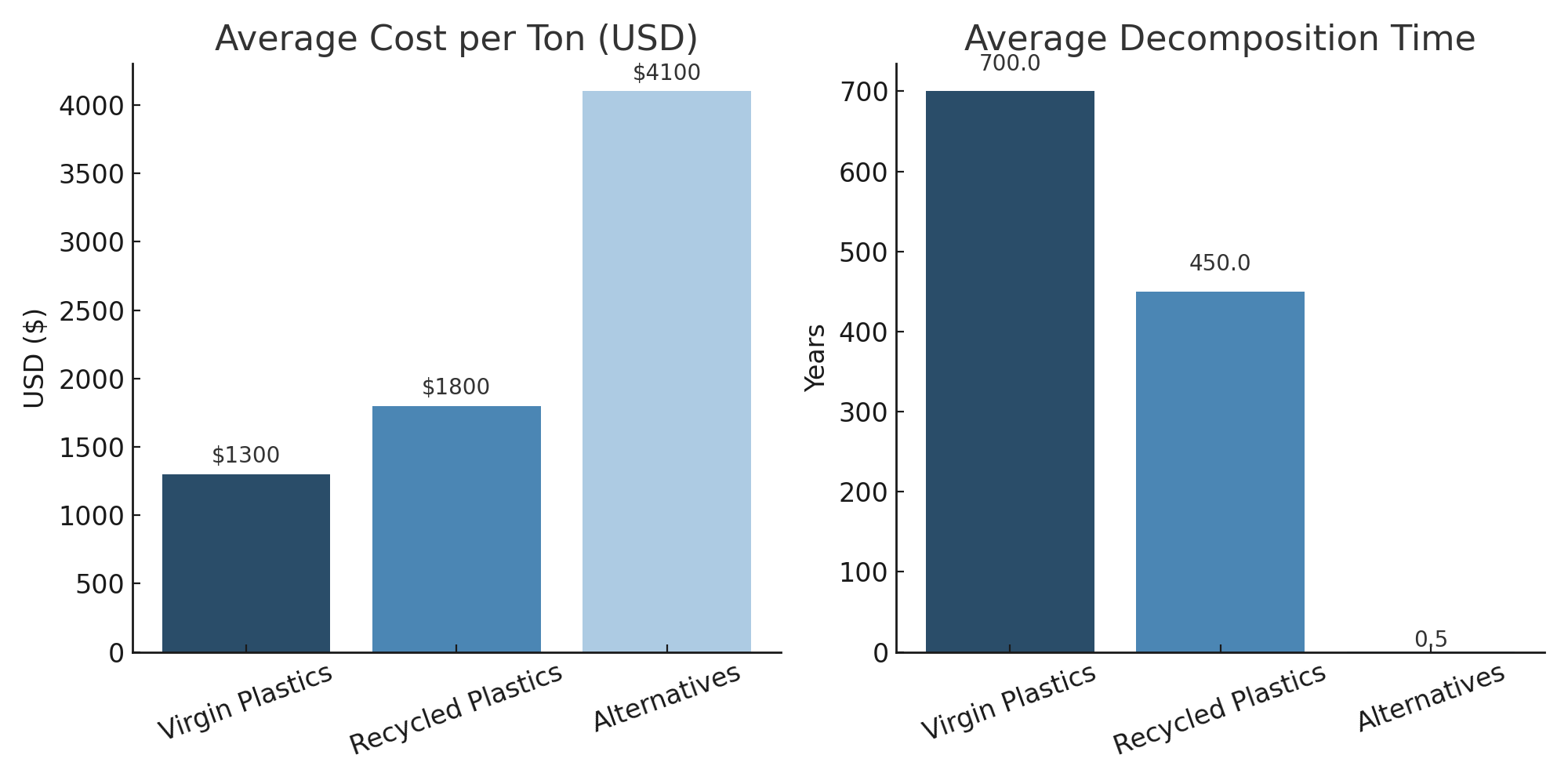

Start in the source – BioBoost Materials

A strategic shift to replace a portion of Nestlé’s packaging with compostable and sustainable materials, made from:

- Food waste side streams (e.g., whey from dairy, cocoa shells, rice husks, seaweed)

- Certified bioplastics like PLA (polylactic acid) and PHA (polyhydroxyalkanoates)

20% of Nestlé’s packaging to PLA may represent an annual investment of $288 million, but it would eliminate over 400,000 tons of CO₂

Why These Materials?

- Bio-based origins: Made from renewable sources like corn, algae, or microbes .

- Compostable: Break down naturally, reducing long-term waste and microplastic pollution.

- Lower fossil dependence: Replace petroleum-based plastics, supporting decarbonization.

- Upcycle side-stream waste: Materials like whey, cocoa shells, or rice husks are repurposed instead of discarded.

- Enables circularity: Packaging returns to nature or becomes raw material again.

- Aligned with Nestlé’s sustainability goals: Supports 100% recyclable/compostable packaging by 2025.

Key Benefits of Switching to Sustainable Packaging

| Category | Benefit | Key Figure |

|---|---|---|

| Environment | Reduces long-term waste | 🌱 Biopackaging degrades in 3–6 months vs. 500+ years for plastics |

| Cuts carbon emissions | 🔻 Switching to PLA reduces CO₂ by ~1.7 tons per ton replaced (EPA, 2023) | |

| Brand Impact | Increases consumer preference | 💚 7 in 10 Gen Z consumers prefer sustainable packaging (McKinsey, 2023) |

| Strengthens market leadership | 🥇 Nestlé is among the Top 10 ESG-ranked food brands globally (S&P, 2023) | |

| Strategic / Financial | Avoids future plastic taxes/fines | 💸 €800 per ton of non-recycled plastic in the EU (EU Green Tax) |

| Enables green financing access | 📈 Up to 10% lower interest rates for ESG-linked loans (Bloomberg, 2022) |

Example of Possible Real Applications

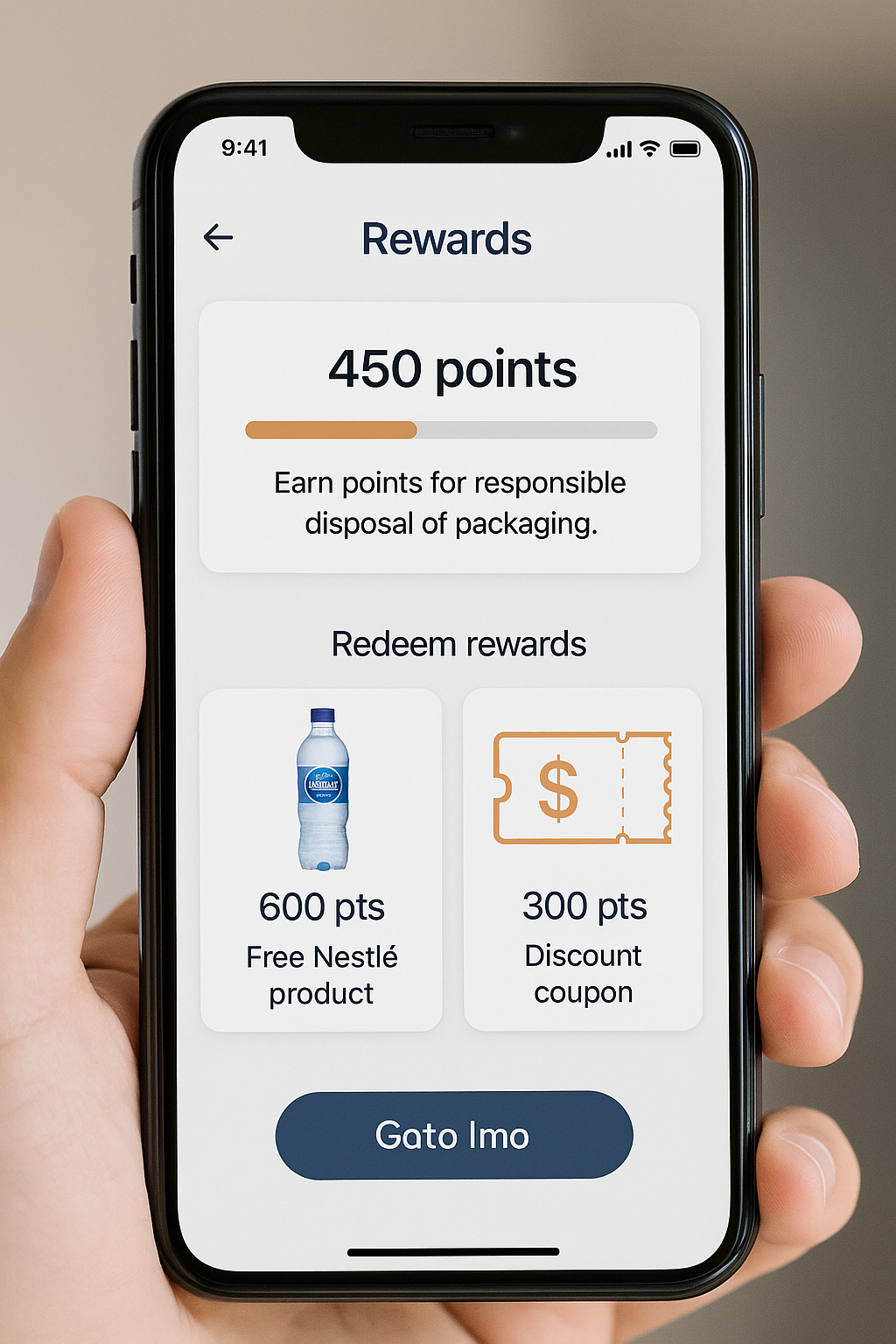

Empowering the Consumer – SmartPack

SmartPack is a digital tool embedded in Nestlé’s packaging. It uses a unique QR code linked to a platform that personalizes recycling instructions for consumers and delivers real-time environmental intelligence to Nestlé.

Experience Flow

- Scan the QR code on the package using a smartphone.

- Costumer see local recycling instructions based on geolocation.

- Earn rewards for returns or responsible disposal (points, discounts).

- Track personal impact – CO₂ saved, waste avoided, contributions logged.

- Collect real-time data by region, product, and user behavior (powered by AI).

Estimated IT Cost Breakdown

| Phase | Estimated Cost |

|---|---|

| App Development | $80,000 – $250,000 |

| Annual Maintenance | 15–20% (~$12,000 – $50,000) |

Key Benefits

| For Consumers | For Nestlé |

|---|---|

| Personalized recycling info | Actionable data by SKU, region, and behavior |

| Eco-rewards and gamification | Greater brand engagement and trust |

| Impact visibility = motivation to act | AI-based design and supply chain recommendations |

| Builds a culture of shared responsibility | Supports tracking and innovation cycles |

SmartPack turns every package into a tool for change — one scan at a time.

End of the Chain – LoopBack

LoopBack is Nestlé’s post-consumption packaging recovery system designed to close the circular loop through smart return stations and crushing machines.

How It Works

- Consumers return used packaging to LoopBack stations (e.g., supermarkets, campuses).

- Packaging is compacted on-site with crushing machines (volume reduced up to 80%).

- Nestlé collects and forwards the compacted material to recyclers or composters.

- Recovered material re-enters the packaging supply chain.

Recommended Model: Start with local partnerships in key cities to test and scale.

A basic smart bottle compactor with detection and compression features typically costs between $4,000 and $10,000 USD, according to commercial listings from manufacturers like Orwak

Key Benefits

On-site volume reduction = lower transport & emissions

Improved material recovery rates

Data insights on consumer participation

Strengthened sustainability leadership & reputation

Risks and Mitigation

Financial

High cost of bio-based materials

Scale gradually, negotiate long-term contracts

Technological

Low QR adoption or app failures

Intuitive UX, clear communication, and tech support

Operational

Complex return and collection logistics

Start with regional pilots and local partners

Scalability & Flexibility

Feasible

Each component (materials, SmartPack, LoopBack) can be rolled out in phases, starting small and scaling up gradually.

Adaptable

Flexible to different market conditions, infrastructure levels, and consumer behaviors.

Scalable

Allows controlled growth—begin with pilot programs, measure results, and expand based on performance.

💻 IT Integration in the Proposal

💡 Digital Innovation

SmartPack digitizes packaging with QR codes and geolocation to connect consumers and sustainability.

🤖 Artificial Intelligence

AI analyzes scanning and behavior data to optimize design, logistics, and engagement.

📊 Business Analytics

Dashboards display environmental and user metrics in real-time to support data-driven decisions.

The Smart Choice for a Circular and Profitable Future

Tackles the entire packaging lifecycle

It’s realistic and scalable

Uses real circular economy principles

Reduces emissions and waste

Empowers consumers through technology

Strengthens Nestlé’s leadership

Thank you for your attention!

I appreciate your time and consideration. Let's build a more sustainable future together.